Before making a purchase, you must grasp the intricate journey that used machinery undergoes. From its initial acquisition to the meticulous inspection, maintenance scrutiny, and performance evaluation, each stage unravels vital clues about the equipment’s past and future potential. By understanding this lifecycle, you equip yourself with the tools needed to make a well-informed decision. But remember, there’s one crucial aspect that ties it all together, ensuring you secure a reliable and efficient investment.

Acquisition Phase

During the Acquisition Phase of used machinery, your primary focus is on sourcing equipment that meets your specific operational needs. This is the stage where you conduct research, explore various options, and negotiate deals to secure the machinery required for your business. It’s crucial to consider factors such as equipment size, capacity, age, and maintenance history to ensure that the machinery aligns with your production requirements.

As you navigate through this phase, it’s essential to establish clear communication with sellers, ask pertinent questions, and request detailed information about the equipment. By actively engaging with sellers and thoroughly evaluating their offerings, you can make informed decisions that benefit your operations in the long run.

Additionally, be mindful of budget constraints and explore financing options if necessary to acquire the machinery that best suits your needs.

Inspection and Evaluation

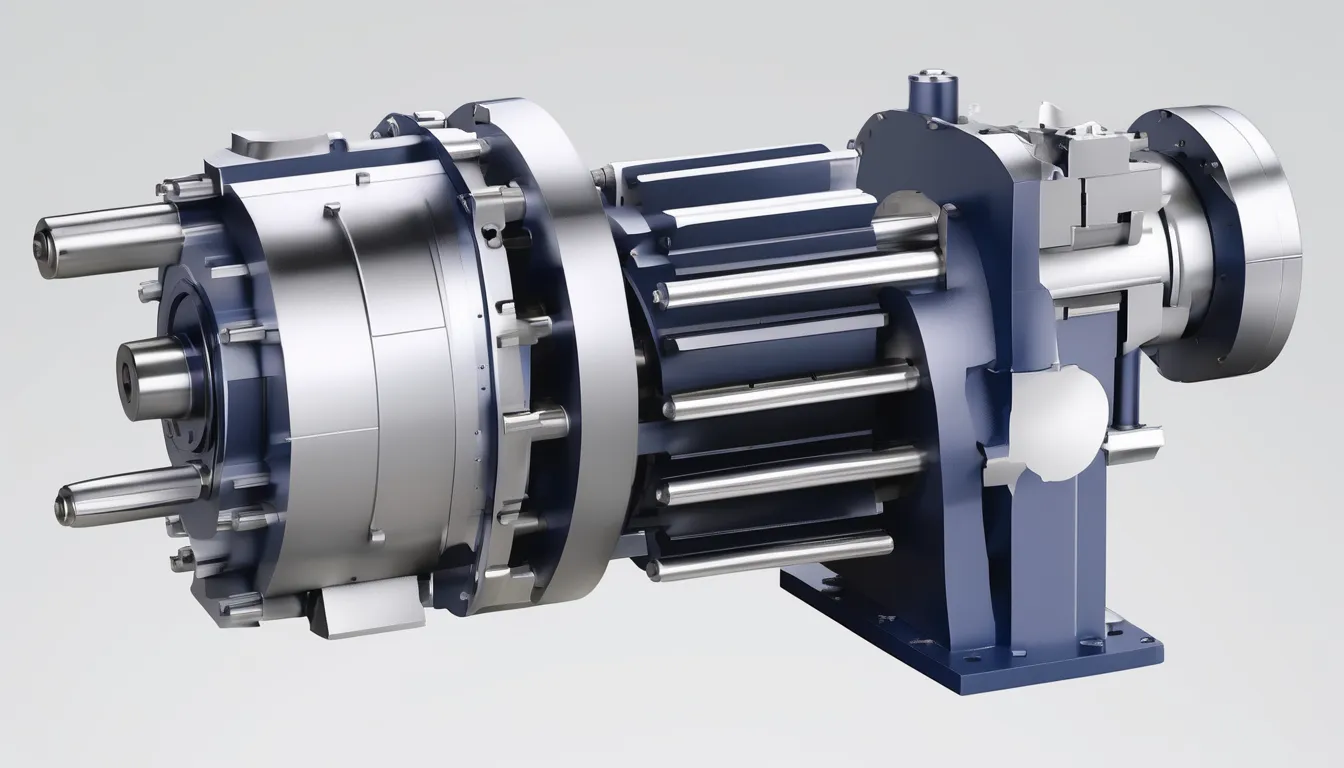

When assessing used machinery, conducting a thorough inspection and evaluation is crucial to ensure its quality and functionality align with your operational requirements. Start by visually examining the equipment for any signs of wear, damage, or missing parts. Test all functions and mechanisms to confirm they’re in working order. Check for leaks, unusual noises, or vibrations during operation.

Utilize testing equipment to assess the performance and accuracy of the machinery. Evaluate the overall condition of the exterior, interior, and key components. It’s important to consider the age of the machinery and how it aligns with the expected lifespan of similar equipment. Look for any modifications or repairs that may affect its functionality.

Additionally, review the manufacturer’s specifications to verify if the machinery meets your operational needs. By conducting a comprehensive inspection and evaluation, you can make an informed decision on whether the used machinery is a suitable investment for your business.

Maintenance History Analysis

How can you determine the reliability and upkeep of a piece of used machinery? One crucial step is conducting a thorough analysis of its maintenance history. By reviewing maintenance records, you can gain valuable insights into how well the machinery has been cared for and identify any recurring issues that may affect its performance.

To help you understand the significance of maintenance history analysis, consider the following breakdown:

| Key Aspect | What to Look For | Why It Matters |

|---|---|---|

| Regular Maintenance | Consistent servicing schedules | Indicates proactive care |

| Repair Records | Frequency and type of repairs | Highlights potential recurring problems |

| Parts Replacements | Quality of replacement parts | Reflects on overall maintenance quality |

Analyzing these aspects will provide you with a comprehensive view of the machinery’s past care and help you assess its overall condition and potential longevity. Remember, a well-documented maintenance history is a strong indicator of a machine that has been well-maintained and is likely to offer reliable performance.

Performance and Longevity Assessment

To evaluate the performance and potential longevity of a piece of used machinery, you need to assess key indicators that can provide valuable insights into its operational capabilities and durability.

- Operational Efficiency: Check how smoothly the machinery operates under varying workloads. Look for signs of sluggishness, unusual noises, or vibrations that could indicate underlying issues affecting its performance.

- Maintenance Records: Review the maintenance logs to see if the machinery has been consistently serviced and if any major components have been replaced. A well-maintained machine is likely to have a longer lifespan.

- Usage Patterns: Understand the previous owner’s operation practices and the environment in which the machinery was used. Heavy usage or exposure to harsh conditions can significantly impact its longevity.

Resale Considerations

Considering the market value of used machinery is crucial when contemplating resale. Before making a purchase, it’s essential to research how well the machinery retains its value over time. Factors like brand reputation, age, maintenance history, and technological advancements can all impact resale prices.

A well-known brand with a strong reputation might hold its value better than lesser-known brands. Additionally, newer machinery models with advanced features tend to have higher resale value compared to older models. Regular maintenance records can also boost resale potential, showing potential buyers that the machinery has been well cared for.

When it comes to selling your used machinery, timing is key. Keep an eye on market trends and demand fluctuations to determine the best time to sell for optimal returns. You may also want to consider refurbishing or making minor repairs to enhance the machinery’s appeal to potential buyers.

Frequently Asked Questions

Are Spare Parts Readily Available for This Particular Model?

Spare parts for this model are readily available. You can easily find what you need to keep the machinery running smoothly. Make sure to check availability before purchasing to avoid any potential downtime in the future.

What Is the Average Downtime Experienced With This Machinery?

You should consider the average downtime experienced with this machinery. It directly impacts productivity 中古工具 profitability. Knowing this information helps you make informed decisions that can minimize disruptions and keep your operations running smoothly.

Can This Machinery Be Easily Upgraded or Modified?

You can easily upgrade or modify this machinery. It’s designed for flexibility and improvements. Get the most out of your investment by customizing it to suit your evolving needs and stay ahead in your industry.

How Does the Manufacturer’s Reputation Impact Resale Value?

Your machinery’s resale value heavily depends on the manufacturer’s reputation. A reputable brand often commands higher prices and attracts more buyers. Keep this in mind when considering your purchase to potentially secure better returns in the future.

Are There Any Known Common Issues With This Type of Machinery?

You should research common issues with this machinery. Check for recurring problems that might affect performance. Knowing potential issues upfront can help you make an informed decision and avoid unexpected costs down the line.

Conclusion

So, before you make that purchase, remember to thoroughly understand the lifecycle of the used machinery you’re interested in. By taking the time to inspect, evaluate, analyze, assess, and consider resale potential, you can make a well-informed decision that meets your operational needs and ensures long-term efficiency. Don’t overlook the importance of understanding the history and potential future of the machinery you’re investing in.